Experience the

Essence of Precision

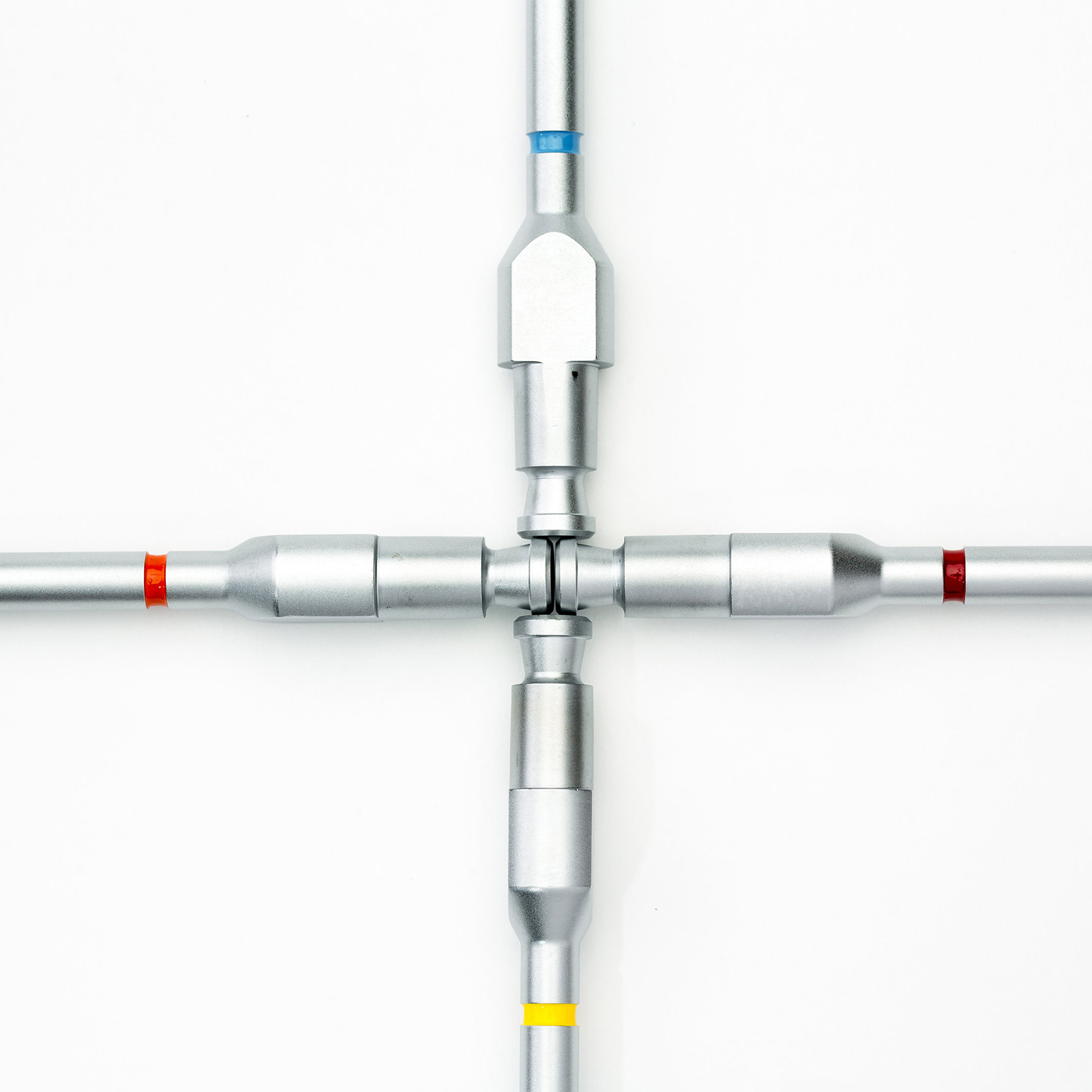

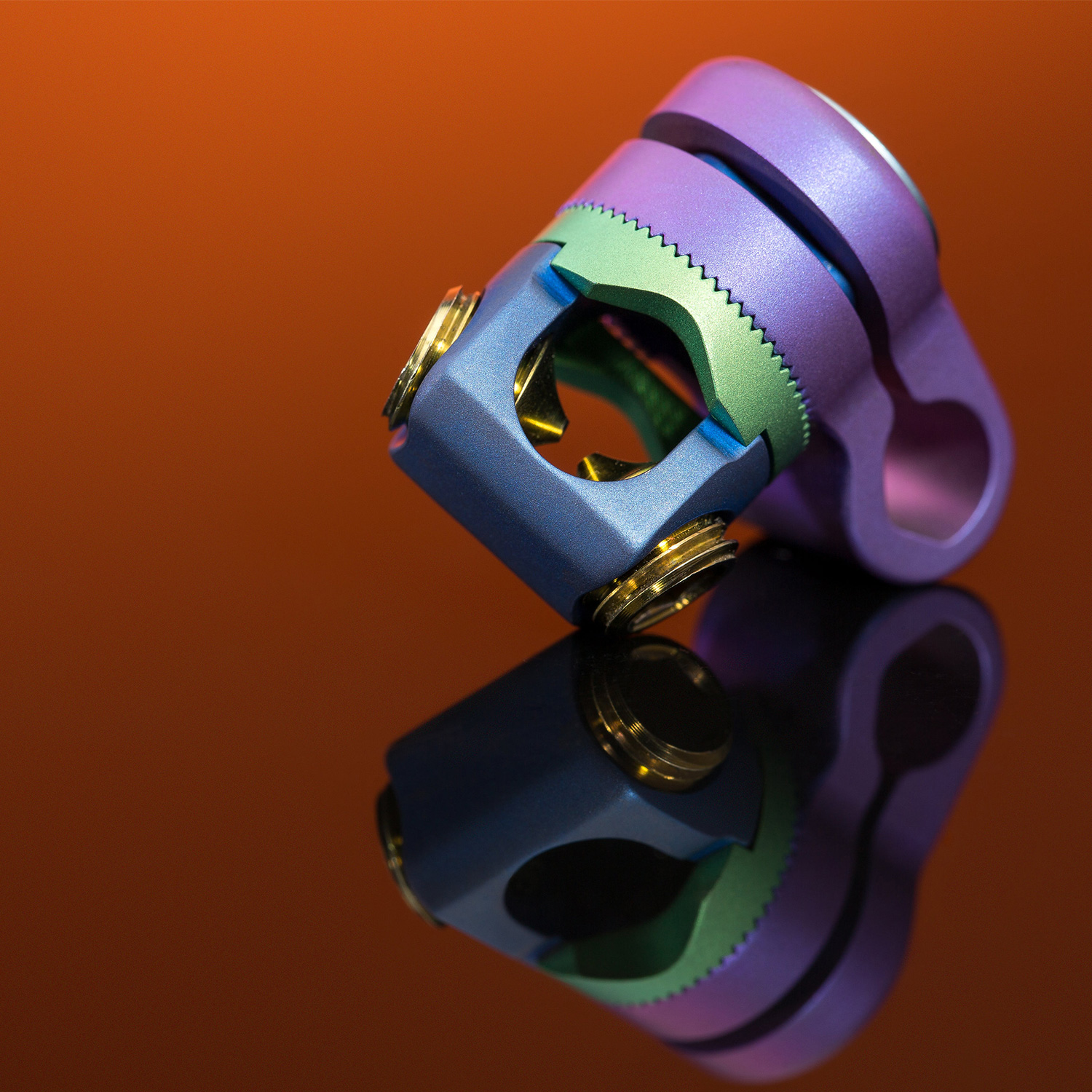

Orthopedic precision instrument specialists

Experience the

Essence of Precision

Orthopedic precision instrument specialists

Jatex was founded upon a simple, yet critically important principle: deliver unequaled quality at a fair price. When manufacturing precision-machined products for the orthopedic and spinal industries, there’s no room for error. For over 25 years, as a family owned and operated business, Jatex has consistently embraced innovation to provide a superior level of excellence.

To us, it’s about being meticulous every step of the way, and this approach doesn't just apply to the production process of implant and instrument components.

We put considerable effort into ensuring that customers enjoy the best price possible. And, we place the highest priority on guaranteeing complete satisfaction – accomplished through on-time delivery and unwavering customer service.

Jatex is renowned for quality, and that’s demonstrated in every step we take, for every single customer.

We specialize in contract manufacturing of components for spinal, joint and extremity medical device industry. We’re driven by a commitment to efficiency and unmatched turn-around times for our customers – while never sacrificing high quality. Our industry experience allows us to make good on this promise.

By employing the latest technology, and being armed with years of insight to tackle any issue, Jatex is the most reliable production partner you can find. Regardless of scope, we always come through. With a facility of over 14,000 sq. ft., we’re efficiently set up to produce lot sizes anywhere from a prototype stage quantity (1-10) to production runs (100+).

All of our CNCs are validated, and here’s an overview of our capabilities:

When needed, we leverage our long-standing relationships with outside vendors to accommodate the following services:

We simply get the job done. Below you’ll find a detailed list of the machinery in our facility.

CNC Milling

CNC Swiss Turning

CNC Turning

CNC Wire EDM

Metal Finishing Equipment

Manual Machining

Quality

Miscellaneous Equipment

Our customer relationships have been successful because no single component leaves our shop without being comprehensively inspected. Due to a rigorous Quality Management System, delivering excellence is never a question.

Our contract manufacturing system has been reviewed and approved by a range of experts within the orthopedic industry. This has granted us a preferred level of supplier status with many highly respected companies – a status we worked hard to achieve, and one we take pride in maintaining.

We received our ISO 13485:2016 certification in October 2017.

We are eager to establish partnerships and continue serving your needs.